![]() Phase 1: Rotorcraft Experimental Facilities and Equipment

Phase 1: Rotorcraft Experimental Facilities and Equipment

Experimental facilities at the University of Maryland are unique among U.S. universities, include articulated and bearingless rotor rigs, a small-scale high-speed rotor for aeroacoustic investigations, composite fabrication and testing labs, a 3D laser Doppler anemometer, a vacuum chamber, a hover tower, various structural dynamic and smart structures labs, and the Glenn L. Martin (GLM) Wind Tunnel. These facilities were upgraded by the addition of a unique 16'x16'x23' anechoic chamber with recirculation for acoustic testing of rotors in hover with microphone arrays and other supporting equipment.

Photos of some of the Key Rotorcraft Experimental Facilities

Baron Autoclave Controlled autoclave with 3' diameter by 4' long chamber. 750 F, and 250 psi. General purpose fabrication of thermoset and thermoplastic composite structures |

0.15 Mach Scale Rotor Blades Blades for the Bell Helicopter 412 0.15 Mach scale bearingless rotor model hub. The four composite blades, which are constructed primarily of graphite composite materials, are shown here |

Anechoic Flow Wind Tunnel Facility 23' by 23' open jet test section. 8' by 8' closed jet test section. David Taylor Research Center, U.S. Navy, Carderock, Maryland |

Bearingless Rotor Rig Stability testing. Body pitch and roll motions about gimbal |

Hover Tower |

Rotor Rig in the GLM Wind Tunnel |

Laser Doppler Velocimetry |

Model Rotor Hub |

Wide Field Shadowgraphy |

Vaccuum Hotpress |

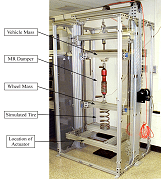

Mechanical Shock Rig |

MTS Testing Machine |

Active interior acoustics control in a rigid enclosure |

Vacuum Spin Chamber 10 ft diameter, 65 channel spin ring, up to 1000 RPM |

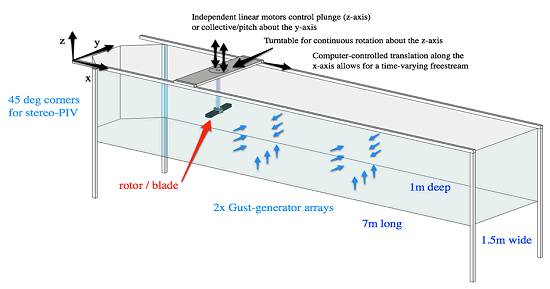

Water Tunnel/Towing Tank Facility

AGRC Projects | Technology Transfers | Example 1 | Example 2 | Example 3